READY MIX PLASTER

NXTFIX mortar is a semi-premix high-quality mortar for the jointing and bonding of AAC blocks. NXTFIX mortar semi-premix consists of cement, graded sand and specialised polymers which combine to give superior strength, water retention and stability. It replaces the conventional method and material of jointing mortar which requires a 12-18 mm thickness with a revolutionary 2-3 mm joint thickness. NXTFIX mortar only requires the addition of water before application to prepare the product for use, reducing the hassle of measuring and maintaining various individual elements to create a conventional mortar.

AAC Block Jointing Mortar – NXTFIX

NXTFIX block jointing mortar is a semi-premix high-quality mortar for the jointing and bonding of AAC blocks. AAC block jointing mortar consists of cement, graded sand, and specialised polymers which combine to give superior strength, water retention and stability. It replaces the conventional method and material of jointing mortar, which requires a 12-18 mm thickness, with a revolutionary 2-3 mm joint thickness. NXTFIX Jointing Mortar only requires the addition of water before application to prepare the product for use, reducing the hassle of measuring and maintaining various individual elements to create a conventional mortar.

Features & Benefits of Block Jointing Mortar

High bond strength

Polymers enhance adhesion, increasing masonry durability and load-bearing capacity, ideal for AAC block jointing mortar applications.

Economical

Requires 3× less volume than traditional mortar save on both materials and labor.

Semi Premix

NXTFIX Jointing Mortar is a semi-premix solutions that only require the addition of water to prepare for application

No Curing Required

Due to water retention polymers, curing is not essential after application

Negligible Seepage

Due to the texture, Chemical bond, and properties of NXTFIX Block Jointing mortar, seepage water penetration through joints is negligible.

Easy Application

Ready-mix saves time, reduces waste, and ensures uniform consistency.

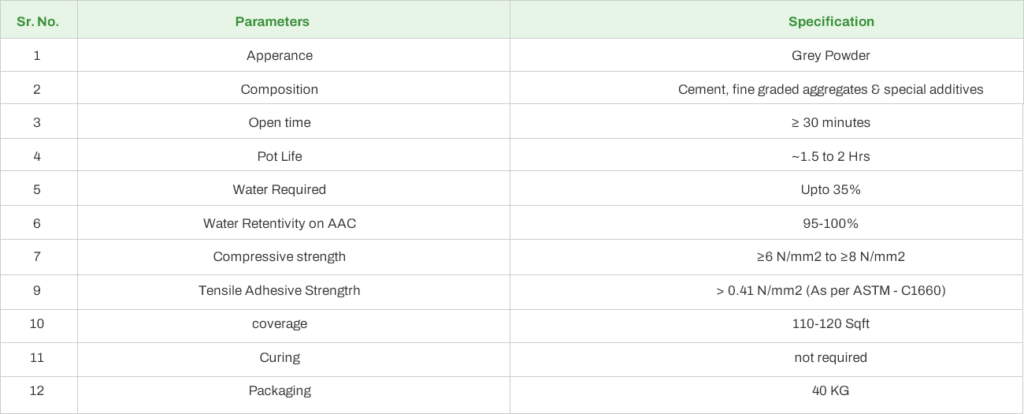

TECHNICAL SPECIFICATION of Block Jointing Mortar

PREPARATION AND APPICATION

Mortar Mixing

In a clean bucket, mix NXT FIX thin bed mortar in 25-30 % of water.

Mixing by Mixer or Tool

Mix first tor 5-10 minutes by hand or electrical mixer to mix homogeneously.

Reaction Time

Allow mortar to stand for 5 minutes.

Mortar Remixing

Mix again for 2-3 minutes. Now thin bed mortar is ready to use.

Mortar Spread

Mortar should be spread on all sides of block in such a way to maintain the bond thickness 2-3 mm.

Setting Time

The setting time is affected by climatic conditions, allow stand-alone time accordingly.

Clean Surface

Before application clean the surface of blocks using suitable tools like brush so that any foreign material is not held on the blocks .

Alignment

use Spirit Level and fibre hammer to remove any air gaps in between blocks for jointing and alignment.

Wet Surface

Wet the surface of blocks before applying mortar.

DND

DO not disturb the wall after application of mortar for at least 24 hours.

KNOWLEDGE BASE