NXTPLAST Ready Mix Plaster is a ready mix cement plaster with high quality polymer additives to sub-stitute for the traditional site mix wall plaster process. The solutionconsists ofprocessed sand which is graded and distributed as per particle size and proportionately mixed, cement and water soluble polymers which act as additives. The application method requires mixing of water before application and the mix is ready for plastering NXTPLAST Ready Mix Plaster can be used for both external and internal plastering

NXTPLAST Ready Mix Plaster can be applied on:

• AAC Block Walls • Clay Brick Walls

• Fly Ash Block Walls • Stone Walls

• Concrete Block Walls • Concrete Surfaces

Ready Mix Plaster – NXTPLAST Premium Cement Plaster

NXTPLAST Ready Mix Plaster is a premium ready-mixed plaster solution made to replace inconsistent, labor-intensive site-mix wall plaster processes. This advanced ready-mix cement plaster, enhanced with quality polymer additives, delivers consistent texture, dependable strength, and easy application.

The premix comprises precisely graded processed sand, cement, and water-soluble polymers that enhance bonding and finish. With just the addition of water before application, Ready Mix Plaster is fully prepared for seamless plastering on both interior and exterior walls.

NXTPLAST Ready Mix Plaster can be applied on:

• AAC Block Walls • Clay Brick Walls

• Fly Ash Block Walls • Stone Walls

• Concrete Block Walls • Concrete Surfaces

FEATURES & BENEFITS of Ready Mix Plaster

High Strength

High compressive and tensile strength increases masonry strength and load-bearing capacity.

Availability

Unlike the uncertain availability of raw river sand, premix bags are available round the year.

Higher Coverage

Due to lower density and high volume, it covers 15-20 sq.ft./bag with athickness of 10-12mm.

Consitency

Due to the manufacturing process and accurate particle size distribution, the premix bags are of consistent quality.

Economical

It provides smooth finish walls even in a single coat. Hence saves time and cost required for putty coating.

Minimum Cracks

Shrinkage cracks are minimised as premix plaster raw materials are tested and accurately mixed with specific particle size and quantity.

Premixed

No site mix and blending of powder is required. Only wateris to be added.

Finish

Surface finish after application is excellent and equal due to best particle size grading, hence maximizing wall plaster performance.

Easy Application

The material is pre-mixed and only water has to be added on site. This makes the process of plastering much easier and quicker.

Minimum Wastage

The wastage caused in the conventional site mix process while sand sieving and mixing material is totally avoided.

Storage

Easy to maintain stock as equal size packaging in bag form is provided.

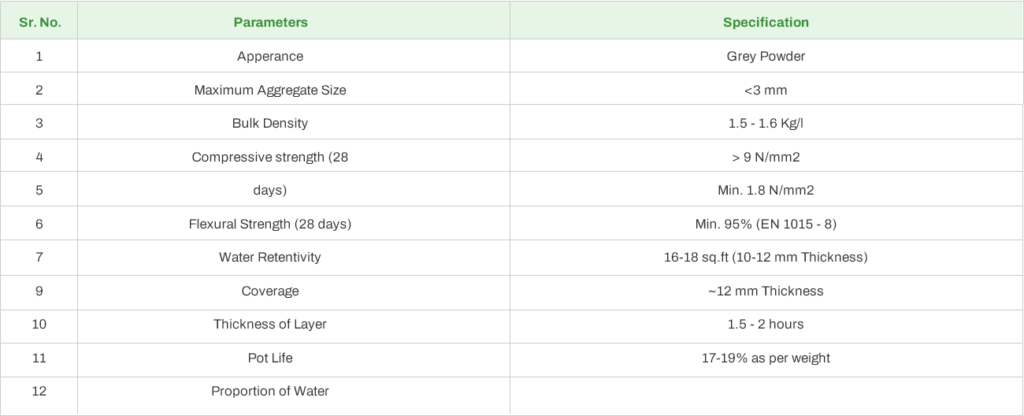

TECHNICAL SPECIFICATION of Ready Mix Plaster

Safety Guidelines for Ready Mix Plaster

- Always wear protective gloves, a dust mask, and goggles while handling or mixing the plaster.

- Avoid direct contact with skin or eyes. In case of accidental exposure, rinse thoroughly with clean water.

- For cases of prolonged irritation, seek immediate professional medical assistance.

- Use the product only in well-ventilated areas.

At Bigbloc Construction, the NXTPLAST Ready Mix Plaster is a non-toxic, non-hazardous wall plastering material, making it safe for use in both residential and commercial projects. However, like all dry mix cementitious materials, it’s essential to follow recommended usage guidelines and safety precautions to ensure optimum results.

The information presented here is based on our in-depth product knowledge, internal lab testing, and years of field experience with ready mix plaster applications. On-site results may vary depending on application methods, climate conditions, and substrate quality.

If you are planning to use application techniques not covered in this document, we strongly recommend that you:

- Contact our technical support team for specific advice.

- Perform a trial application or patch test before full-scale usage.

This document does not constitute a legally binding warranty or performance guarantee. For all contractual matters, please refer to our general terms and conditions of sale.

Before starting the application, ensure you have the latest version of this ready mix plaster data sheet and consult our experts for any project-specific queries.

PREPARATION AND APPICATION

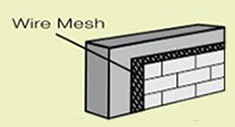

Concrete Block Joints

All concrete and block joints must be covered with a chicken wire mesh.

Mix Preparation

In 6-7 liters of potable water add 1 bag ot NXTPLAST Ready Mix Plaster.

Remixing

Re-mixing should be done for 5-10 minutes.

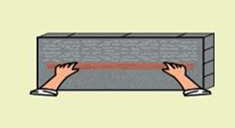

Leveling

Atter final coat ensure proper levelnq with the help of appropriate tools.

Surface Clean

The surface should be free from oil, grease, paint, loose plaster or dirt particles.

Leave to React

Leave the mix to react for 5-10 min and remix before use.

Apply on Wall

The mixture should be thrown while the cement slurry is wet, ensure levelling with the help of tools.

Water Curing

In-normal weather, NXTPLAST doesn’t need water curing for the first 24 hours. After the plaster is completely dry, curing should be done 2-3 times for 2-3 days. In abnormal weather conditions, curing for 5-7 days is required.

Wall Wetting

Dampen the wall before application of plaster.

Cement Slurry

Apply cement slurry, If tho surface is smooth and dence, the surface should be made rough.

Second Coat

If 2nd coat is required, ensure grooving on first coat to provide good grip for 2nd coat.

KNOWLEDGE BASE